Picture Frame Moulding - Step 1

We're finally ready, it's time to start making some picture frame moulding!

Using the steps to figure out the size of our picture frame let's say we're making a 12" x 14" frame with rails that are 1 3/4" wide and 3/4" thick.

I like to be efficient in the shop - it saves time, wood and money so instead of cutting four individual rails I cut two long rails.

Doing that produces all four rails of the frame.

This way, you perform several tasks twice instead of four times.

Work Smart!

If you're making picture frame moulding in batches, this is even more important!

So let's figure out how wide and how long our initial piece of stock needs to be to make our moulding.

Measuring Picture Frame Moulding

Width: if each rail is 1 3/4" wide, round them up to 2" (this leaves some wiggle room), meaning we need a board that is at least 4" wide to start.

I like to throw in even more wiggle room, usually another 1/2", to the total. This leaves plenty of room for the wood that is lost to the saw blade - 1/8" - and for milling and sanding to final width.

The total width for our stock then starts at 4 1/2". Feel free to give yourself more wiggle room if that makes you feel more comfortable.

Length: our goal is to cut 2 long rails that will each produce one 12" rail and one 14" rail.

Don't make the mistake of simply adding 12 and 14.

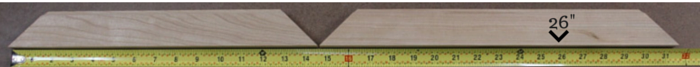

If you do, you'll come up short as the picture below demonstrates.

When making picture frame moulding, the trick to measuring the length needed is to account for the miter cuts you make.

When you make a miter cut on a board that is 1 3/4" wide, the inside edge of the board is about 1 3/4" shorter than the outside edge.

So, if you start with the 14" rail and cut a miter into each end, the inside length is actually around 10 1/2". As we discussed, on the Frame Anatomy page, the inside edge measurement is how the frame size is determined.

So, to figure out the proper length you need, add the width of the rails to each end (1 3/4" for each end of the rail) to the measurement of both rails you intend to produce.

For example: our goal is to get one 12" and one 14" rail out of a single, long rail, so we would do this:

12 (final length short rail) + 3.5 (the total length of miter cut on each end) +14 (final length long rail) + 3.5 (the miter cut on each end) = 33

I round up to 36 inches just to give me a little extra space in case there are splits or checks at the end of the boards and to account for the space in between both rails as you cut them out (check out the picture above).

So, whether you're milling your own wood or you're buying it pre-milled, you know you need a board that's at least 4 1/2 inches wide and 33 to 36 inches long.

Set your table saw fence 1 7/8" from the blade and rip 2 long rails.

Cleaning up the Rails

|

We're making progress on our picture frame moulding. But, before you do any routing you need to clean these two rails up and make sure they are identical in width and thickness. If you're using raw lumber now is the time to pass your rails through the planer to create uniform thickness and width of both rails. |

|

Use several very shallow passes to clean up both faces and make sure they are the same thickness.

Pre-milled wood is typically sold at 3/4" thick, so you can't (and really shouldn't have to since it is pre-milled!!) plane the wood.

Once both faces are clean and uniform turn the rails on their edge and run them through the planer again making several shallow passes on both edges to clean them up and make sure they are the same width - 1 3/4".

If you don't have a planer you can still clean up the edges by snugging a rail up against the table saw blade and locking the fence in place then pass each rail through again (once on each edge if necessary).

This method will remove a light shaving of wood and will clean up any marks. It will also ensure your rails are identical in width (just be sure you do the exact same thing to both rails so they stay identical).

You can also choose to sand the edges clean - it just requires more work and time.

Now you're ready for Step 2 of the making picture frame moulding process!

Notice how making picture frames builds a lot of other woodworking skills too?!

Leave any questions, thoughts, tips or suggestions below!

© Copyright 2012 -2022 by Al Pilato, picture-frame-it-yourself.com

Privacy Policy Disclaimers

Updated November 18, 2022

Have a question or a comment? This space is for you! Leave it in the box below.